Foundry Industries

Specifications and Applications of Quartz in the Foundry Industries :

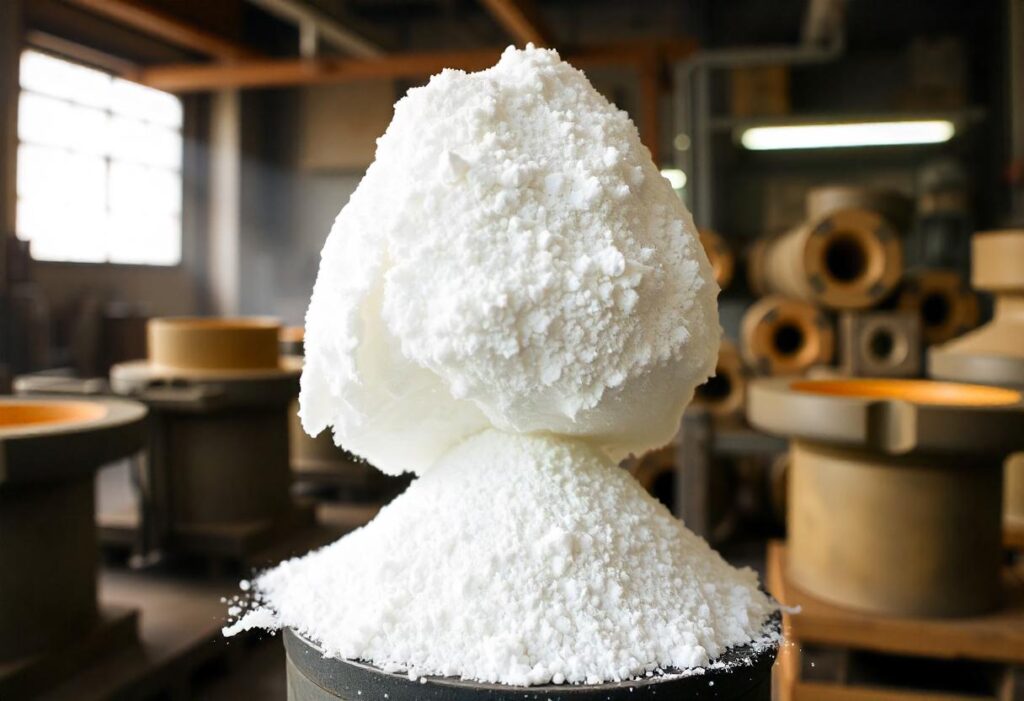

Quartz (Silica) Powder :

High silica sand used in foundries differs from that used in the glass and refractory industries. Foundry sand should have a well-developed grading, preferred shape, and size, in addition to meeting the required chemical composition. It should be free from mica content. The grain size, shape, and distribution significantly impact the molding characteristics of the sand mixture. This standard applies to both natural and crushed sands.

Silica powder is an excellent refractory material for molding applications. It is particularly used in steel foundries for dressing molds and cores, as well as for mixing with molding sands.

Silica flour is utilized to enhance temperature strength, high density, and resistance in metal crushing, washing, and grading processes. It is derived from high-grade quartz, partite rock, or white silica sand, or other sufficiently pure deposits to produce the desired material.

Our Specifications :

- SiO₂ content : 99% and above.

- Fe₂O₃ content : Below 0.04% (Depending on the grade of quartz).

- Mesh sizes : 200 mesh, 300 mesh, 325 mesh, and larger. Custom sizes can be manufactured as per requirement.

- Grain sizes : 0.1mm to 8.0mm.