Silicate Industry

Specifications and Applications of Quartz in the Silicate Industries :

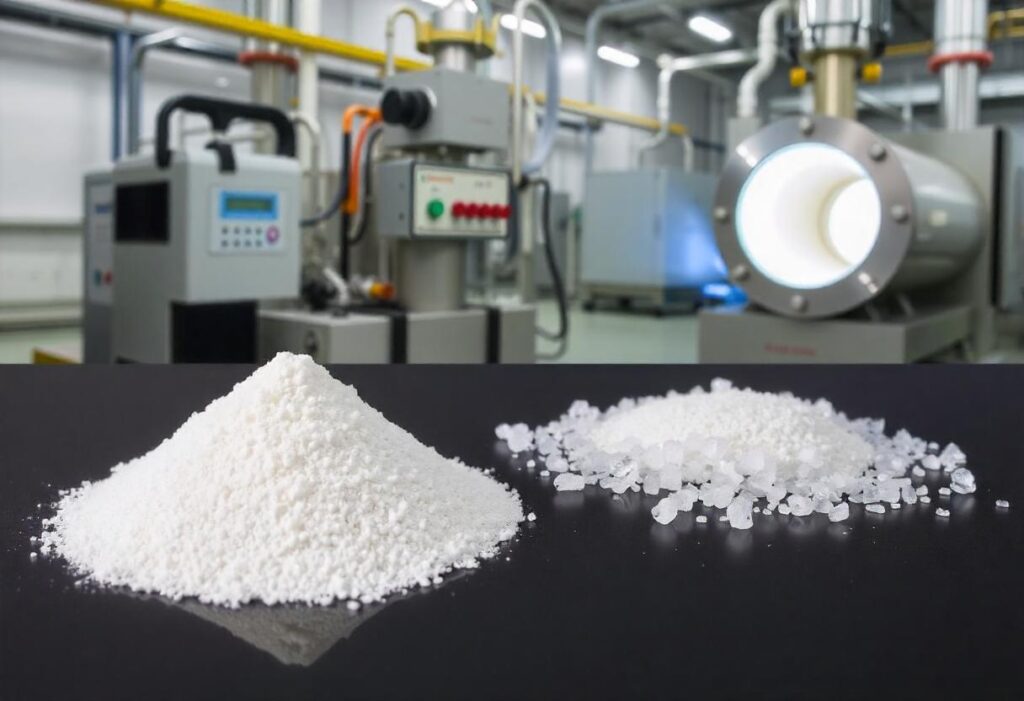

Quartz (Silica) Powder & Granules :

Sodium silicate is produced by fusing silica sand or quartz powder (20-100 mesh) containing 99% SiO₂, less than 0.25% Al₂O₃, 0.03% Fe₂O₃, and a combined CaO/MgO content of 0.05%, with sodium carbonate at temperatures between 1200°C and 1400°C. The Na₂O₃ ratio can be adjusted to produce a variety of products. Similarly, potassium silicate can be made using potassium carbonate instead of sodium carbonate with silica minerals.

For ferroalloy production, quartz should contain more than 98% SiO₂, less than 0.4% Al₂O₃, and no more than 0.2% each of Fe₂O₃, CaO, and MgO. Quartz should also be free of phosphorus or arsenic, as these elements can affect the reduction process in the electric furnace.

Our Specifications :

- SiO₂ content : 99.8%.

- Fe₂O₃ content : Below 0.002%.